| ANGOLO ANGLE UPTO | ANGOLO F FACTOR F |

|---|---|

| 5 | 1,25 |

| 10 | 1,00 |

| 20 | 0,75 |

| 30 | 0,45 |

| 40 | 0,30 |

| 45 | 0,25 |

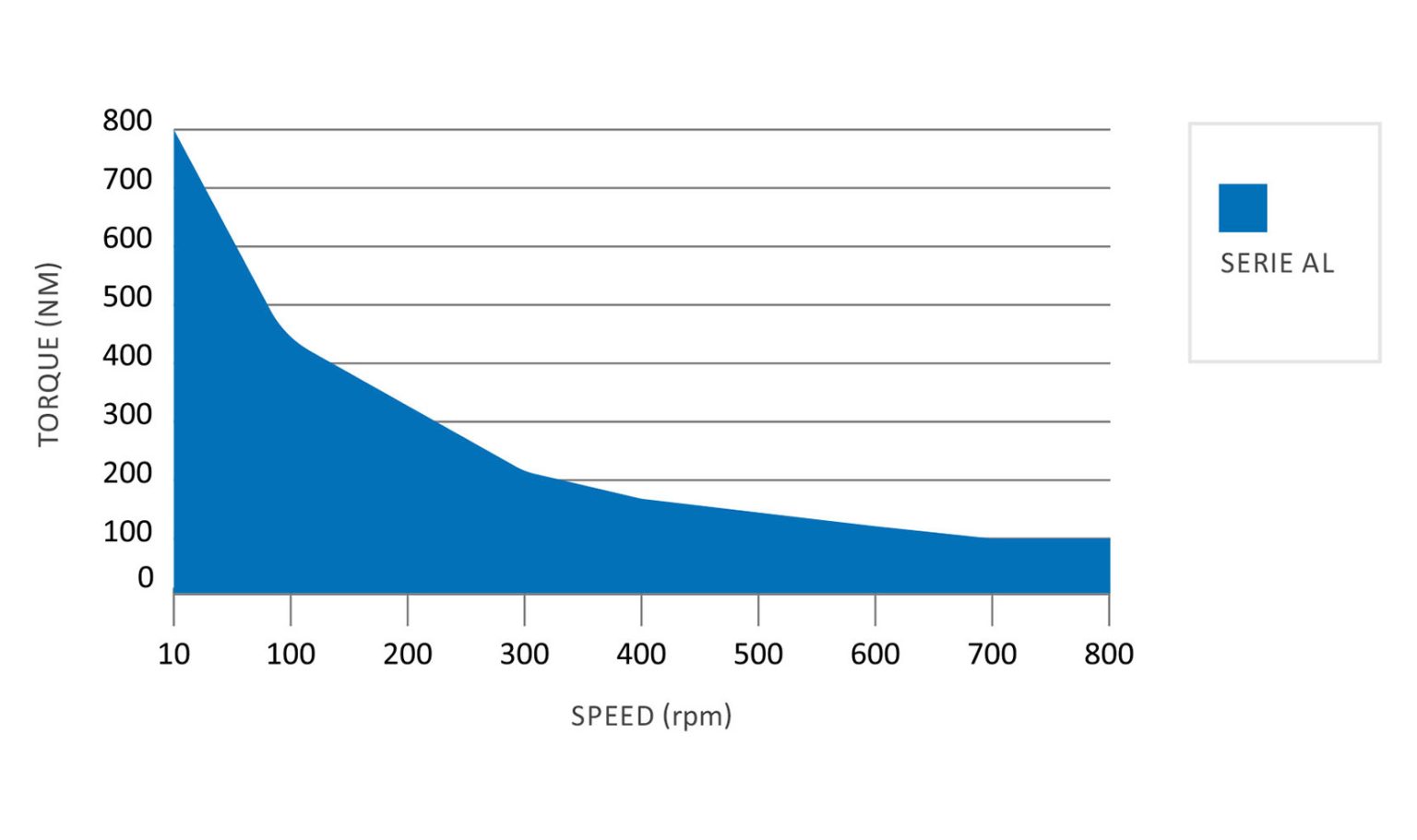

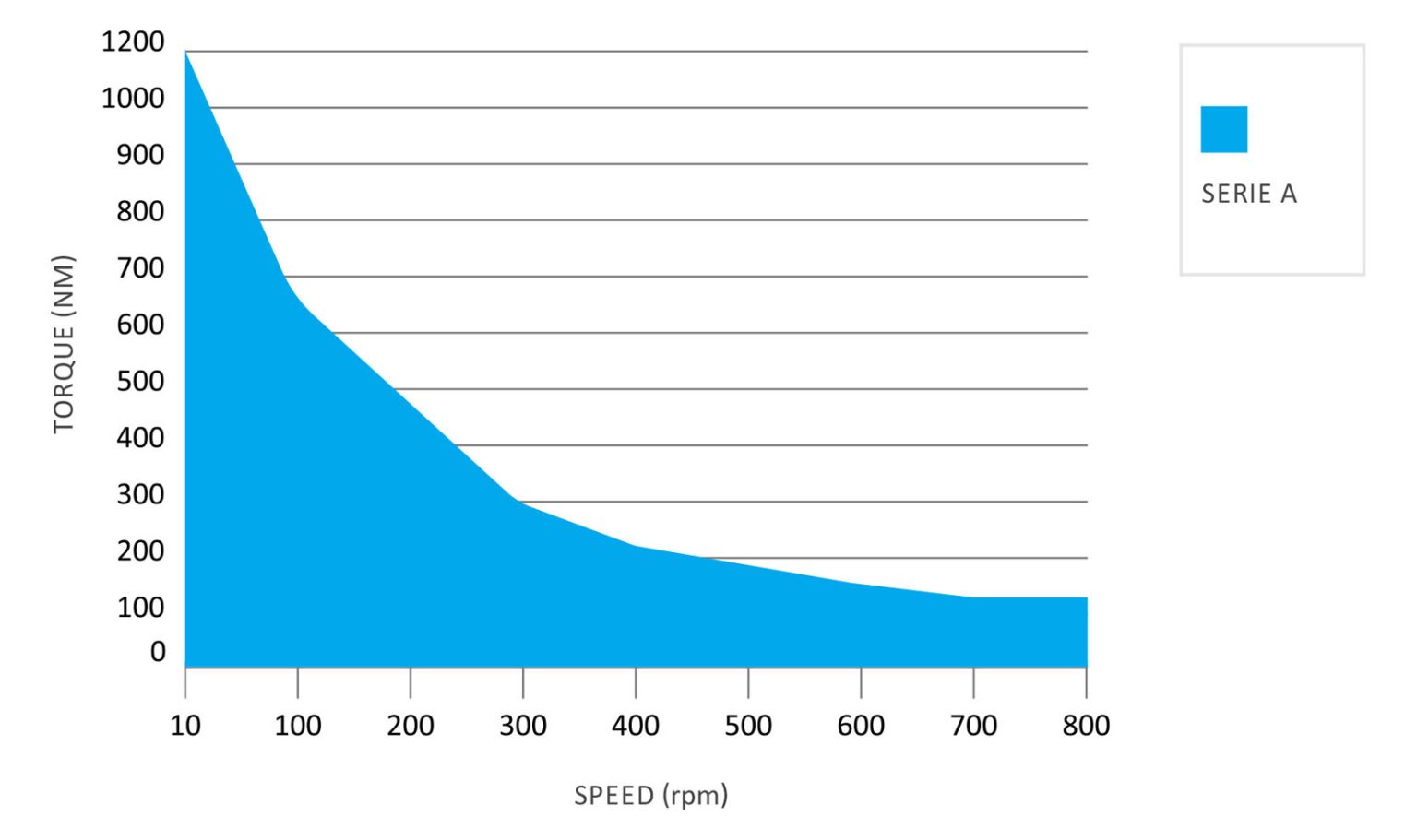

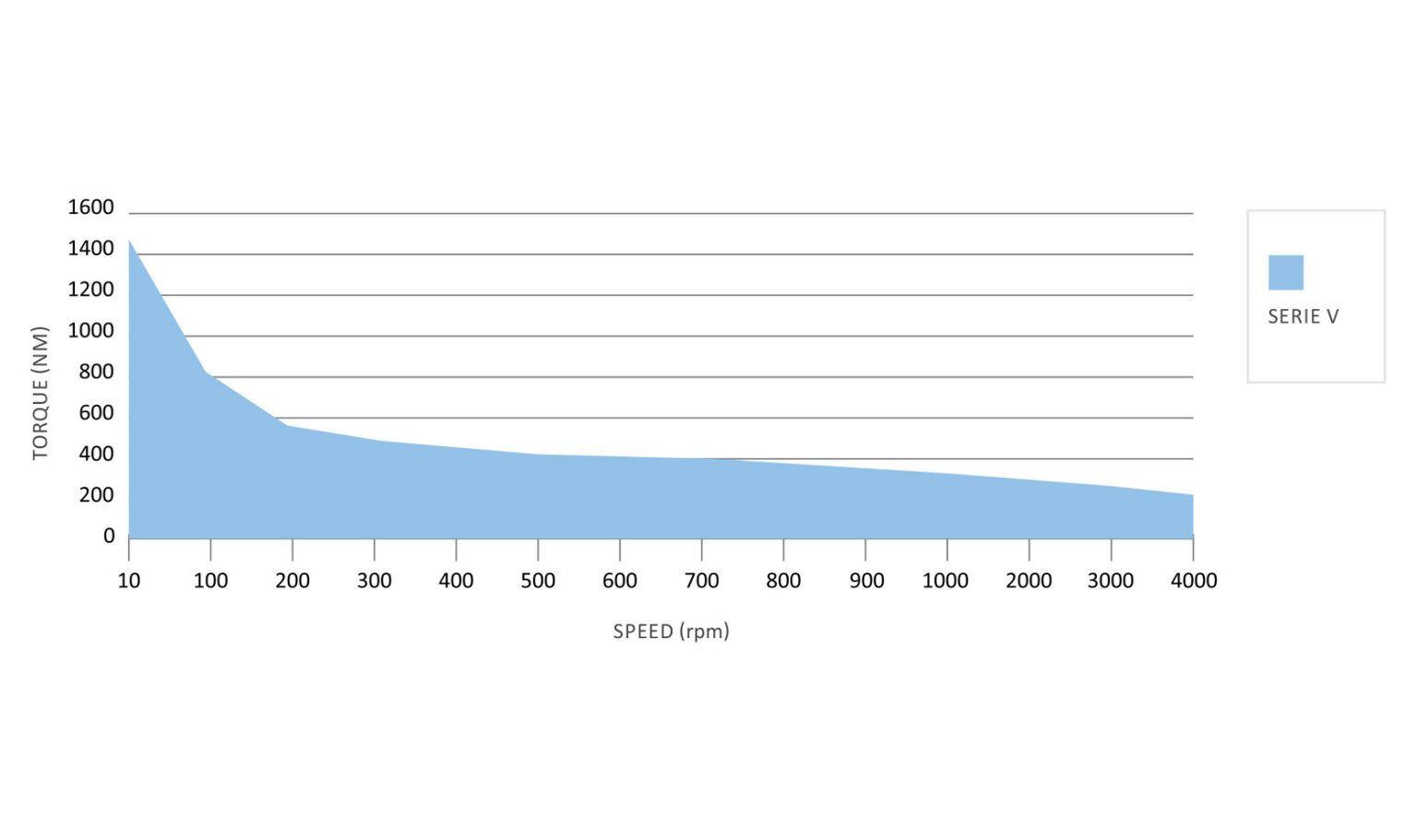

The tables give the maximum allowable torque (expressed in Nm) calculated on the basis with an angle of inclination of 10° and continuous use.

If the inclination angle is over 10°, the values shown will be reduced in accordance with the torque factor shown below.

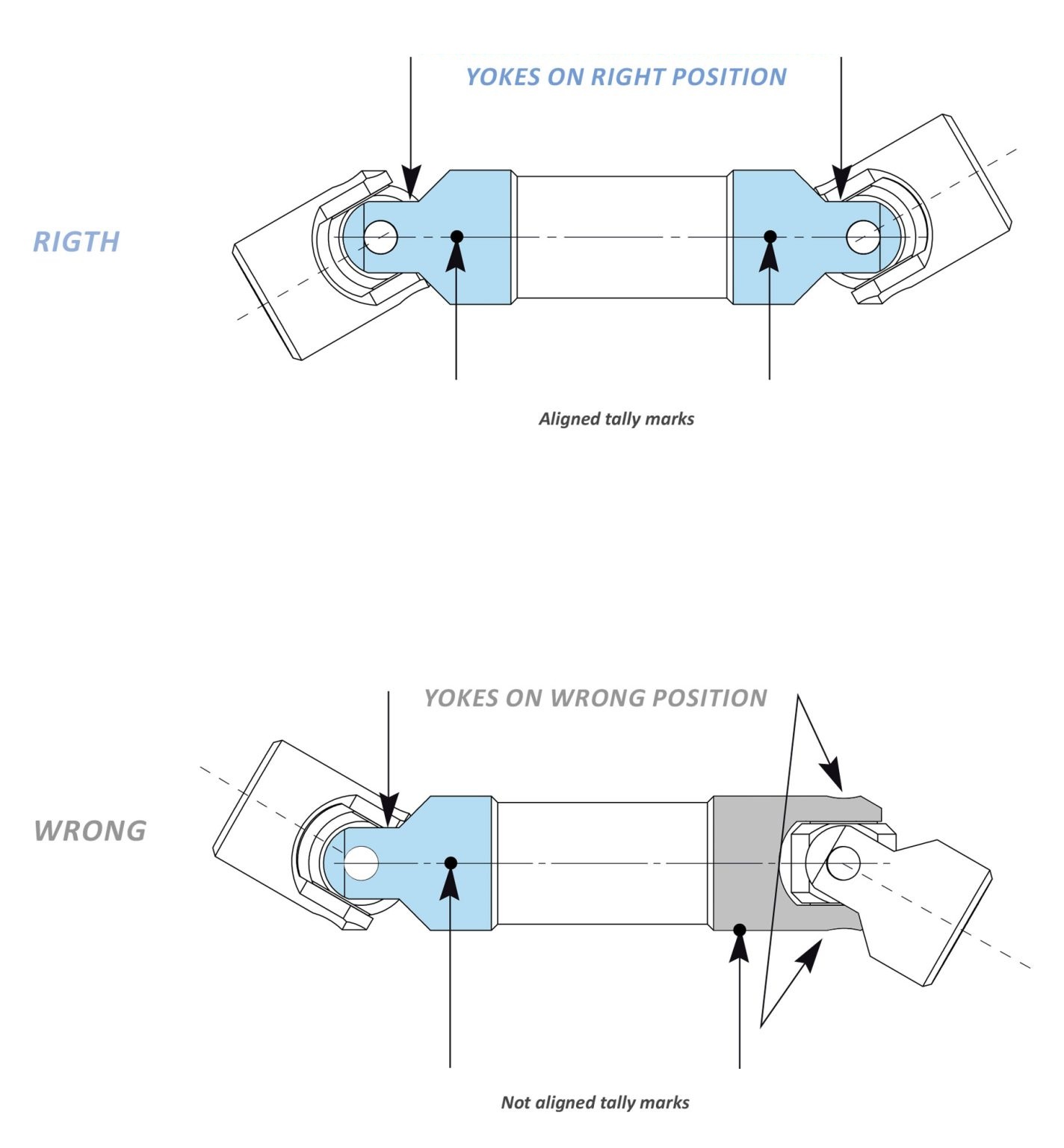

The strict compliance with the following conditions is the essential premise for a perfect working

The maintenance of ROTAR® products is easy and fast, allowing the user an economic and time saving.

For the greasing frequency, please refer to the DATA SHEETS included in this catalogue.